BAM 2017-16 BB SLD RLR LFTR SET .815" RLR- .210" O/S FOR SPRING PRESSURES OVER 650# $946.00

Pro Plus 2000 Series lifters feature 4-column design for ultimate strength and rigidity while minimizing mass. Deep roller bearing pocket provides maximum roller beaing shrouding, maxamizing rigidity and thrust surface area with smooth rounded edges that minimize lifter bore wear.

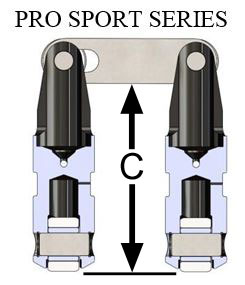

Minimum "C" 2.325" -- Maximum "C" 2.500" Minimum "C" 2.325" -- Maximum "C" 2.500"

| Roller Diameter |

Seat Height |

Weight/Pair |

| 0.815" |

1.93" |

262g |

Triple Alloy Steel Billet Lifter Bodies machined on state of the art CNC equipment.

Machined with “one and done” concept for ultimate relational accuracy of all part features.

Superior 3D CNC programming removes sharp edges that scrape and damage lifter bores.

Heat treated for maximum strength, hardness and straightness in ISO certified furnaces.

Precision Ground Bodies for proper fitment in aftermarket and stock lifter bores.

Link Bars made of hardened, high strength, and high ductility Nickel-Chromium Alloy Steel.

The fully hardened alloy steel button is secured with a non-removable, high strength, fatigue resistant rivet.

Premium Alloy Steel Needle Roller Bearings feature crowned outer rings, micro-polished and micro-sorted roller needles, hardened and nitrided bearing steel axles.

Pressure fed oiling provides continuous oil to the axle and roller bearing.

Additional reliefs on each side of the roller slot allow engine oil from the cam lobe face to lubricate the needle rollers.

Edge Orifice design push rod oiling won’t clog and rob upper valve train of engine oil. This feature can be modified to increase oil flow to the top.

All lifter bodies will clear both stock and aftermarket .300" tall lifter bores. |