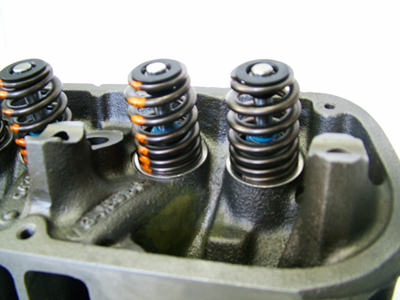

#1---Beehive Springs & Retainers | 1/6/2014

Dave Hughes |

We have been using and selling High Performance Beehive springs and retainers for several years now and have a selection that will meet the needs of most all Mopar applications. This includes L.A. & Magnum engines, the new Modern 5.7 & 6.1 Hemi's as well as Big Block engines.

The most popular springs for small block and modern Hemi heads are the 1120 and the 1122. All of our Beehive springs are wound from premium quality, superclean ovate wire. They are a better quality than most race springs available on the market today.

We currently offer 4 different springs and 2 retainers to fit most needs. To read more about each part number and view their specs, click on each part number below.

Springs: Retainers:

When using Beehive springs in place of conventional springs the open pressures can be reduced by at least 10%. This is because the retainer and valve spring (specially the upper coils) are so light, due to their small size, less open pressure is required to control the retainer, springs and valves. The weight loss can be in the neighborhood of 75-100 grams removed from the valve sideof the rocker, which is the most important side. This weight loss is better (and a lot less expensive) than switching to titanium valves. More RPM, faster---beehive springs!

More good news. Spring surge is a big problem in straight-type(non-beehive) springs. The surge is harmonic resonance or vibration in the spring, created when it is rapidly compressed and released, as in a running engine. SpinTron testing has shown that straight springs move around a lot (an unbelievable amount) in a running engine, due to these harmonics. You can actually see the retainer wiggling around in the breeze, like it was waving goodbye. Sometimes, lock(keepers) float around loose in the retainers. In the surging springs, you can see the coils spread apart and compress together of being compressed or released, indicating the varying spring pressures at max lift or on the seat. Scary stuff. What this tells you is that accurate valve control is a nightmare and an accident waiting to happen. Think about this as you watch the "Cup" cars running at 8800+ RPM for 3 or more hours. Don't you think that their engine builder doesn't have ulcers?

A SpinTron is a machine that looks somewhat like a dyno, but it drives the engine. It is used to test (among other things) valvetrain dynamics and harmonics. With high speed photogragraphy and video, the gyrations of the valvetrain can be recorded for viewing later in terror-filled hours. It is hard to believe!

Well, there is relief available for flat tappet cam and hydraulic roller cam users--beehive springs! The beehive springs have very little, if any, harmonic resonance, due to their varying diameter from top to bottom. The beehive springs have many features that make them a better spring choice. The tapered design does not have the harmonic resonance capability of the straight design, virtually eliminating that problem. The small diameter at the top of the spring allows a very small, lightweight retainer(9 grams vs 36 grams) to be used (see photo). Not only is the retainer lighter, but the single beehive spring will replace a much larger and heavier dual spring assembly.

Depending on application, anywhere from 75-100 grams can be reduced from the valve side of the rocker arm. The weight reduction on the valve side of the rocker arm translates directly into high-RPM valve control with lower spring tension. A win-win deal.

Not only that, but with flat-tappet cams we are looking at reduced cam-and-lifter wear or failure (or maybe more lift, but that's another subject). The lighter open pressure also allows hydraulic cams (especially hydraulic roller type) to rev higher and extend their power band. The wire that is used in beehive springs is not round, like normal spring wire. It is an ovate shape, which distributes the stress over the spring's surface better. The material used in the wire is of a higher, purer quality steel than is found in most straight springs, so you can expect them to cost a little more. Hey, you expected all of these good thing for less? Only the government can "claim" that. |