Ritter Racing Blocks. Now available in a variety of lifter angles and configurations.+

This part cannot be ordered online. Please call to order.

Now Available!

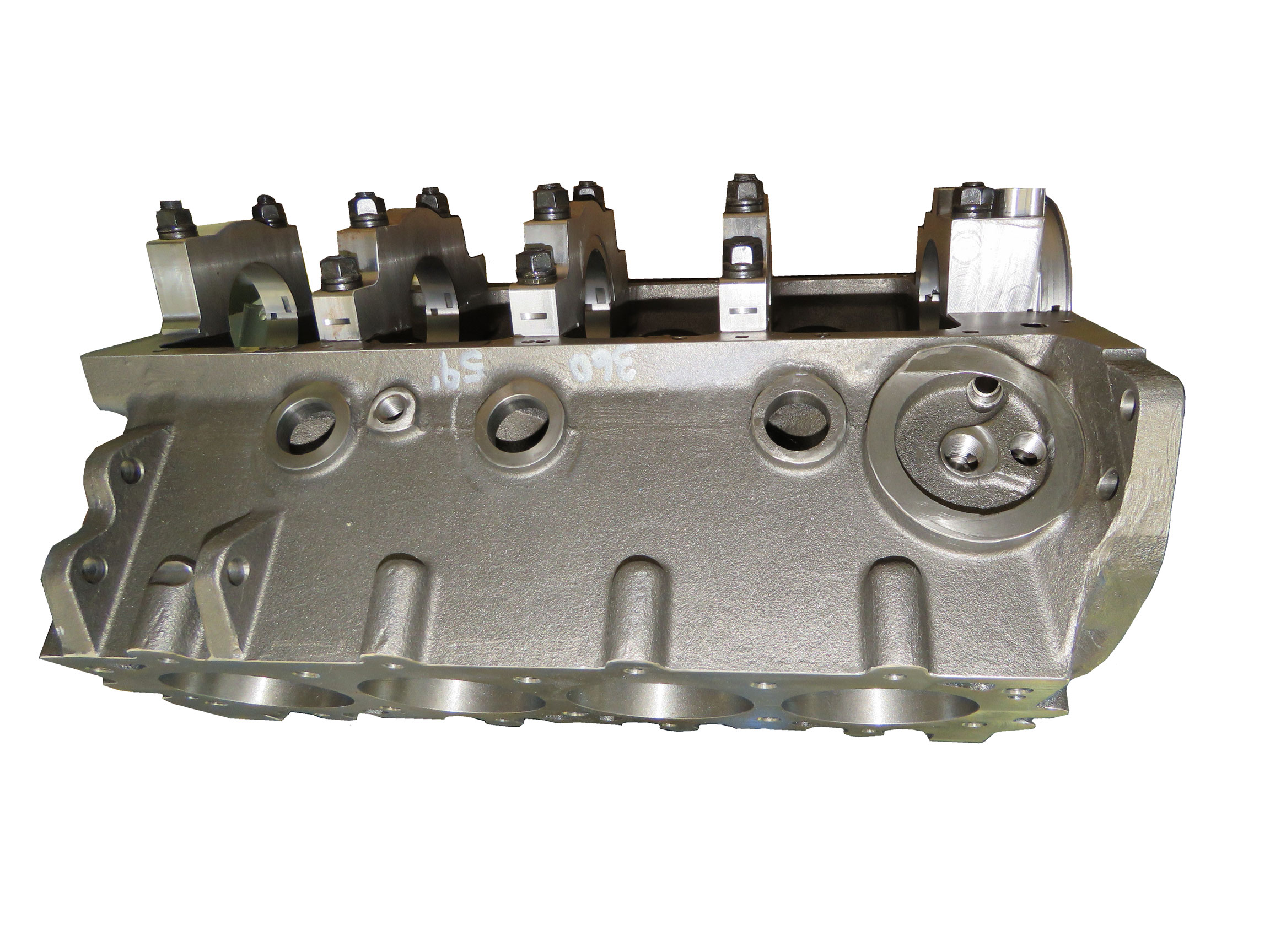

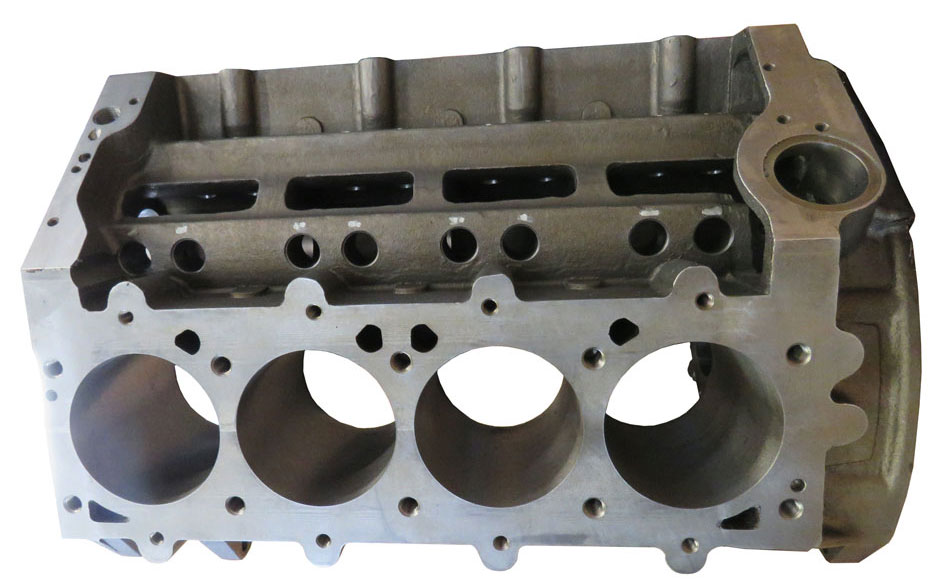

No more searching the junkyards or hoping that Mopar Performance still has the parts available, and we can supply them all. The last key piece in this puzzle is the small block cylinder block. This block (shown below) will have 9.600" deck height. The block pictured here has 360 mains and 59º lifter angles and has a rough bore diameter of 3.900", standard cam bearings, and can go to 4.250". It is a Siamese bore block. When equipped with a 4.150" bore the block weighs 215 pounds.

This block oils to the rockers using a pushrod oiling system like the Magnum engines. "LA" oiling through the block & heads is an option.

Blocks can be custom ordered with 9.000" deck, 48° lifter angles, 340 Mains, and 55mm cam bearing bores.

And, for you chatters...... this block is cast a little East of Bejing.....like in Indiana, U.S.A.

These blocks are not assembly ready. They will require finish bore & hone, possible line hone and final deck height cut.

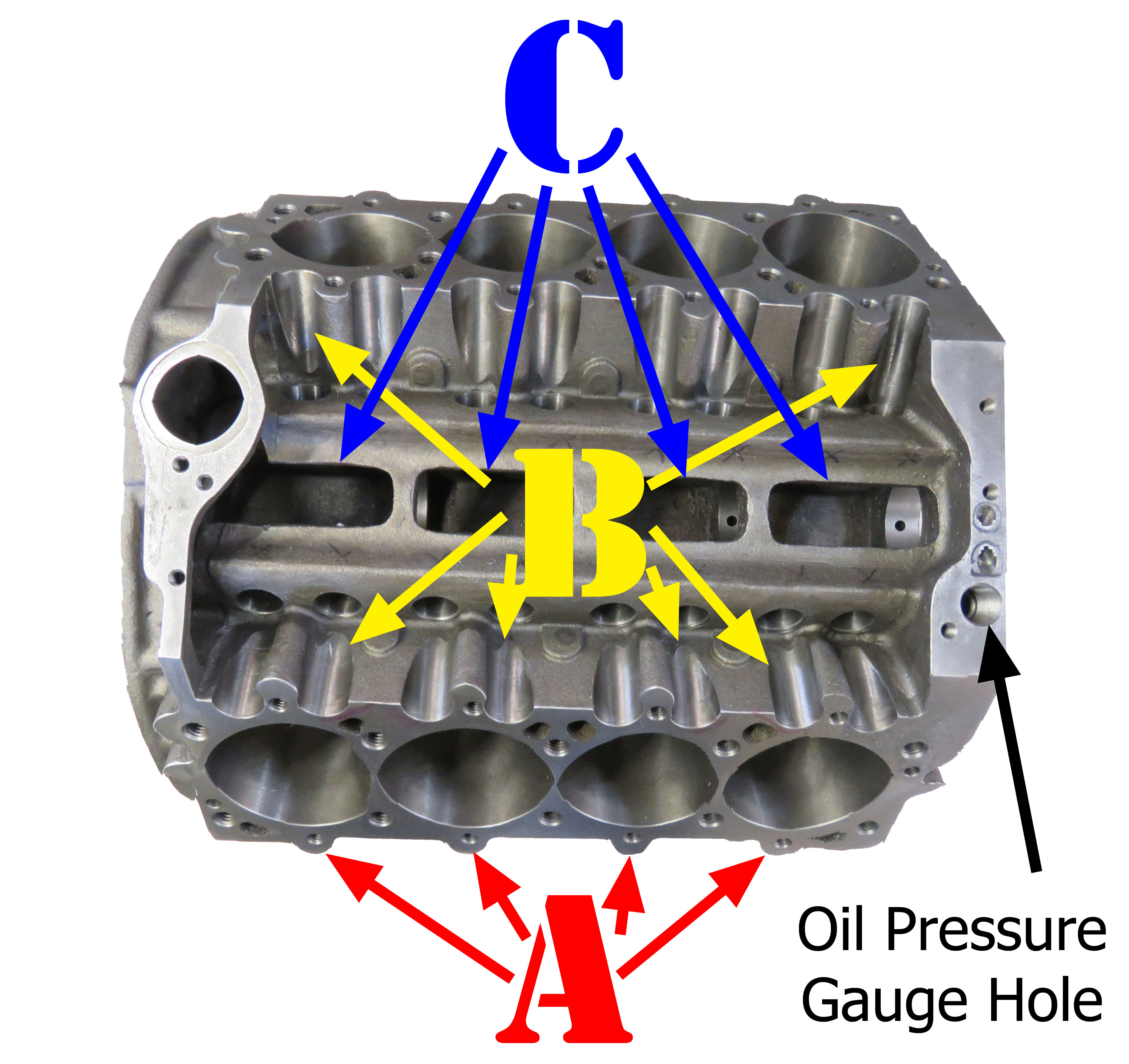

1. The top of the block.

Note: All photos are of blocks with the 59º lifter angles.

Note: The extra in-board and out-board head bolt holes. “A” For 18 bolt heads like W-9 or Edelbrock Victor Jr heads; if you want to use them. The 10 bolt for standard L.A. and Magnum style heads are still there in the standard location . “B” The “pushrod” channels are not really for the pushrods. They are for tooling access for the 59º lifters and will not appear so visibly in the 48º block. Note: the four rectangular openings above the cam. “C” These are actually drains for oil returning from the heads. The normally open area below the cam is closed off and all the return oil drains out at the end of the cam channel, directly to the oil pan. This eliminates the windage created by the return oil. The oil pressure is taken at the larger hole on the front China wall.

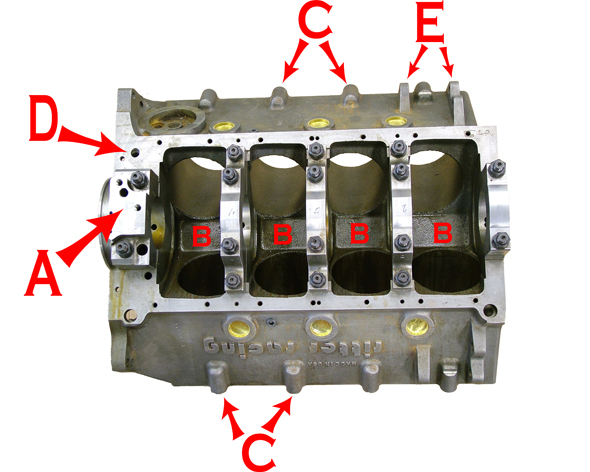

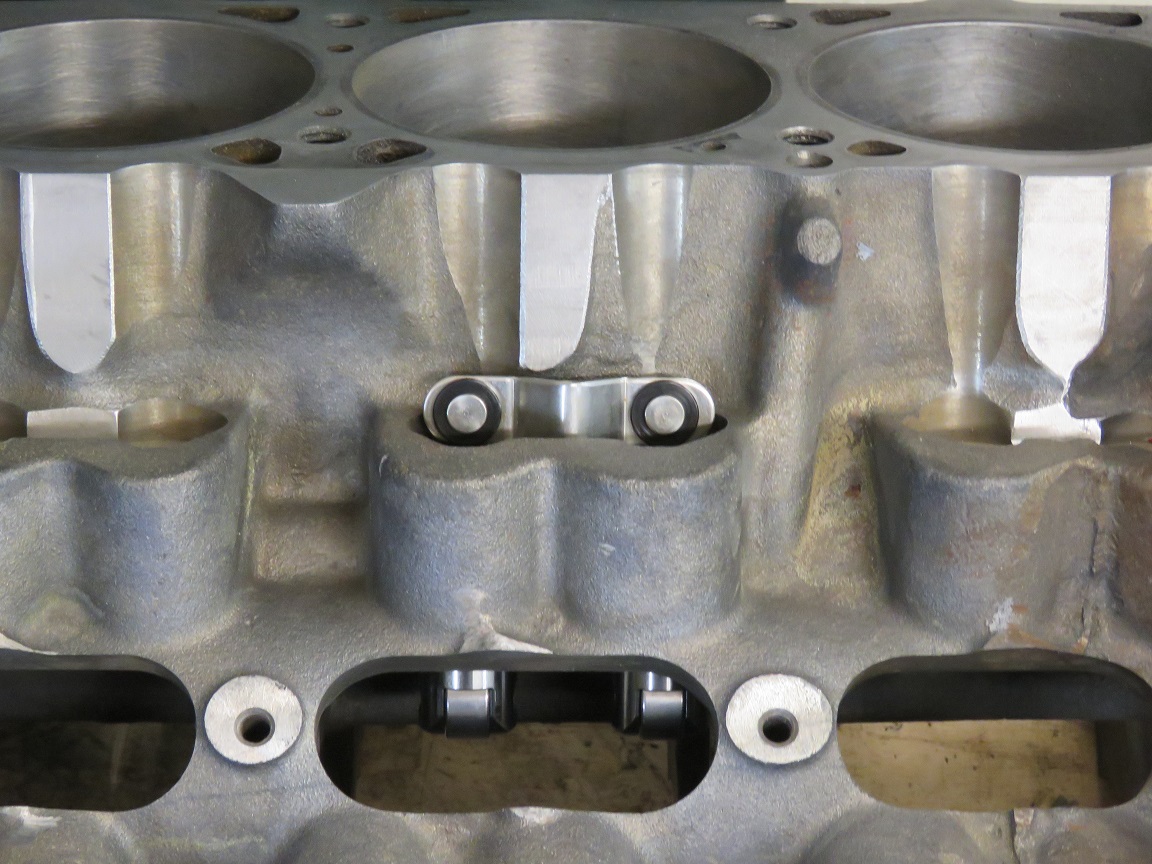

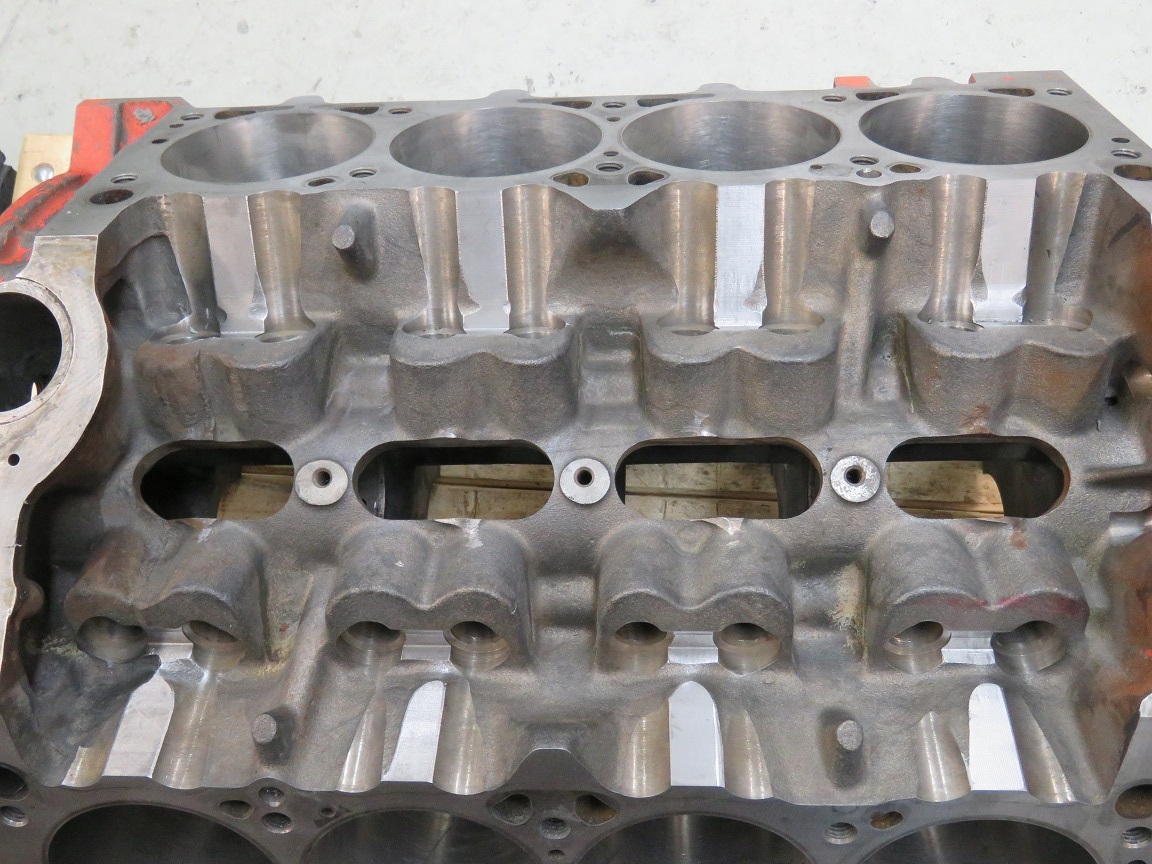

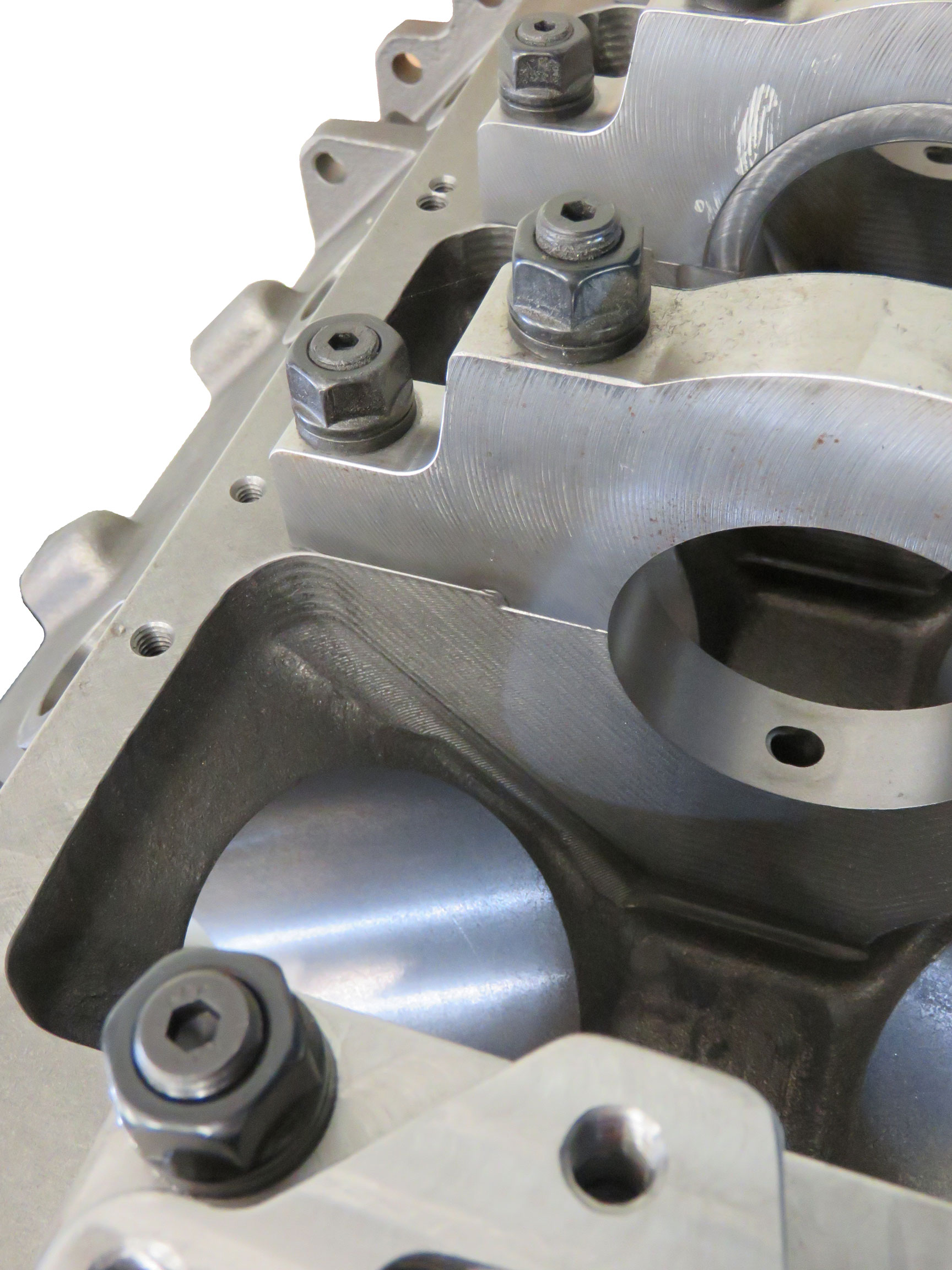

2. Bottom View

The main caps are all billet steel and the standard oil pump location is used for the standard 360 oil pump “A”.The coverage area below the cam is obvious in this view “B”. The out board head bolt lugs are very obvious in these views “C”. The large hole “above” the rear main cap is the drain hole for the rear of the cam chamber “D”. These blocks have the standard L.A. motor mount bosses “E”.

3. The front of the block reveals the super thick deck (approx. 900” thick) at the ½ moon shaped water passages “A”. This block can be decked to 9.000". The oil passages around the cam are a mixture of new and old design. The holes just above the center of the cam bore of the right and left hand sides are the conventional lifter bore oil feed passages as found on standard blocks “B”. The hole at about the 8:00 position is the priority oil passage to the main bearing “C”. The hole at the 7:00 position, half and half off of the machined surface is the front drain for the cam channel “D”. Otherwise, it is stock. The lifter bore oil feed holes “B” are blind and end just past the last lifter bore on each bank.

These blocks oil the rocker arms through the pushrods. "LA" style oiling system is available as an option through Hughes Engines only.

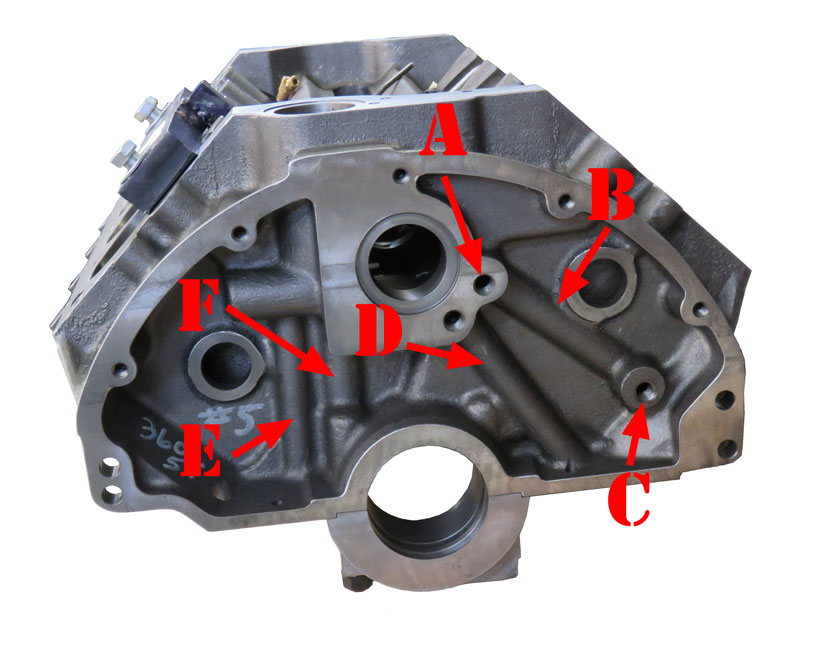

4. The rear end is a lot different. The bell housing bolt pattern and dowel locations are standard small block locations. The passage at the 4:00 position “A” is the main bearing feed passage and it is fed from the ribbed passage “B”. That is directly fed from the oil filter exit passage “C”. There is no hidden plug to divide the passages like in the O.E.M. blocks “D” is one of the rear drain lines for the cam channel “E” is a 2 nd rear cam channel drain. “F” is the passage for the oil pump drive shaft.

The blocks as they come from Ritter do not have an oil passage for the rear cam bearing. The oil passage is on an angle in a very narrow position. At our shop, we have a special drill fixture to drill this passage and all blocks we sell will have this oil passage drilled.

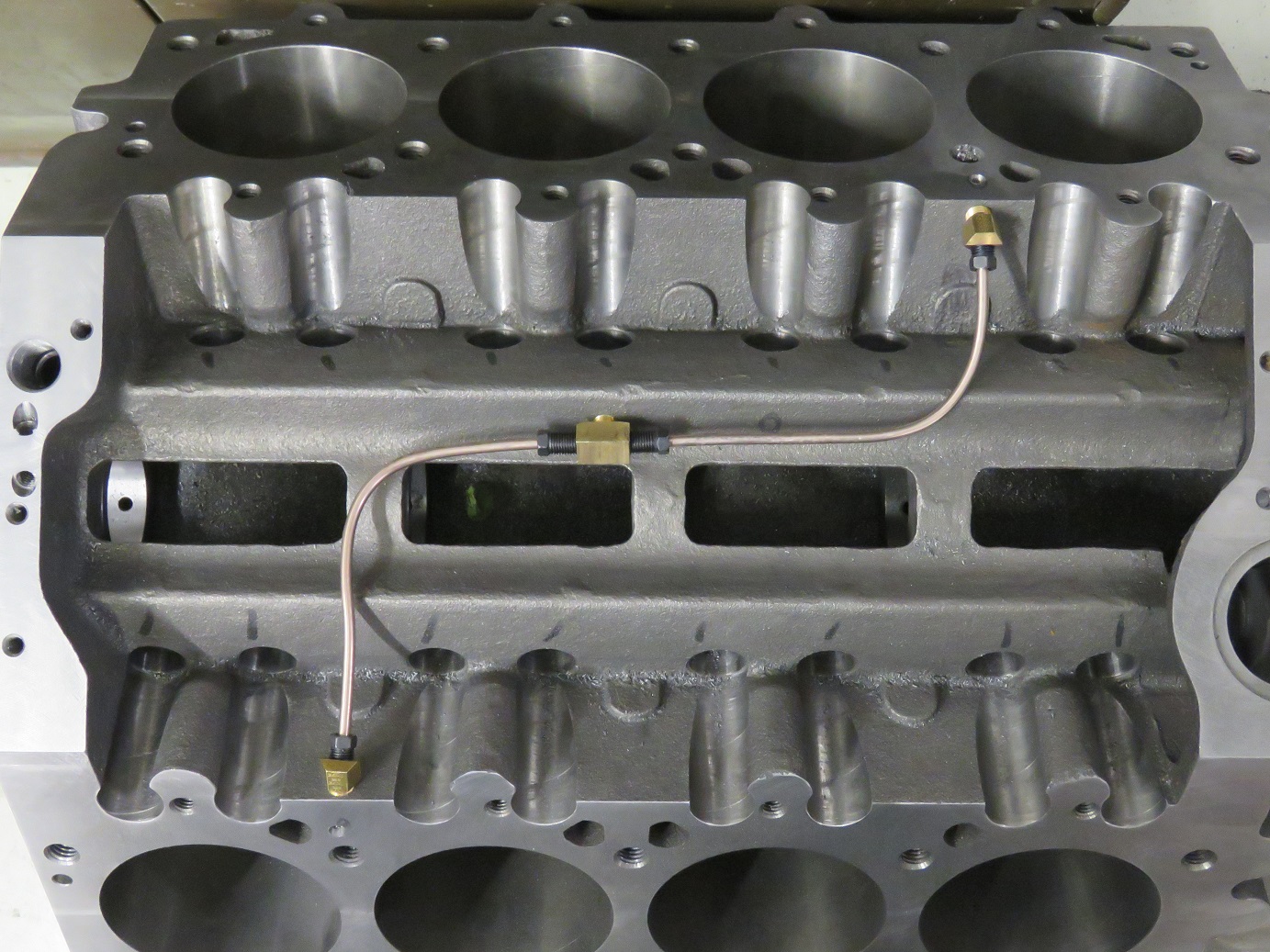

5. This is viewing from the pan up past the main bearing bore to the bottom of cam channel.

The block is bored to use standard cam bearings.

6. The passenger side of the block. Note: The nice wide filter sealing area and outer bosses for outer row of bolt when using the 18 bolt heads.

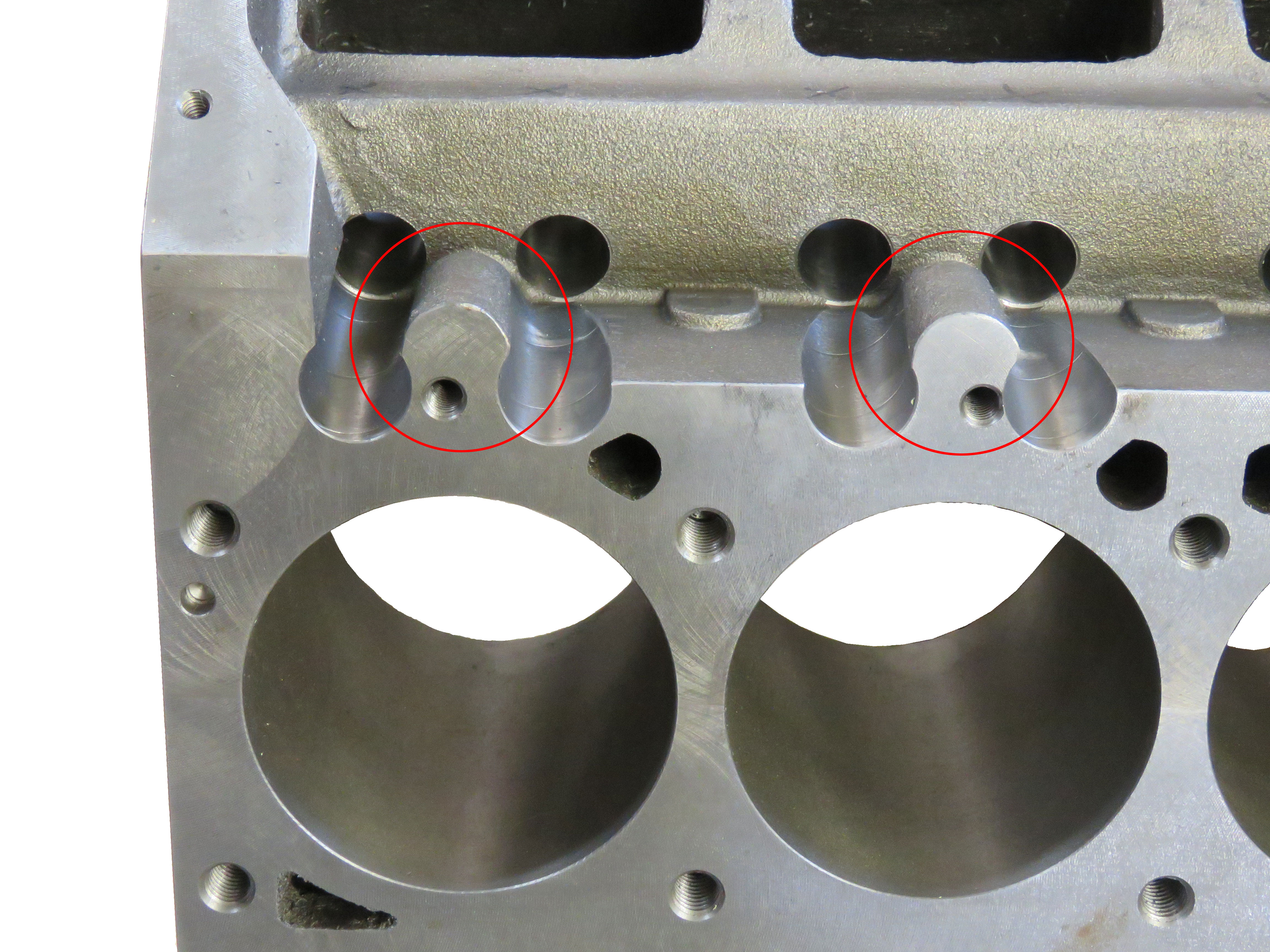

7. Close-up of the lifter bores and machining required for the 59º lifters. When ordered with 48º lifter angles all the extra machining will not be required. With 48º lifters, the lifter bores will move in toward the cam channel openings. You may be able to use solid roller lifters with the 59º angles in these blocks but it would take considerable grinding. The inner head bolt bosses would not be required to be drilled and tapped as shown here, 59º heads do not use them. If you are using 10 bolt heads, the areas circled in red in the photo below can be milled off and our hydraulic roller lifter set #5321 or solid roller lifter set #4723 can be used in this block.

59° Lifter in place

The bosses between the lifter bores are milled away to allow mechanical roller lifters to be used with 59° angles.

7A. Blocks can also be machined with 48° lifter bores.

8. Close-up of the rear, near the distributor, end of the closed in cam channel. Note: the extra material on lifter bosses for moving the lifter bores in to the 48º angle.

NOTE: No Rear Oil Pressure Port

NOTE: No Rear Oil Pressure Port

9. The main bearing bulkheads and the pan skirts are all full thickness. Just like all of the factory race blocks. There are NO WEAK AREAS on these blocks. Blocks come with ARP bolts and hardware.

If you need an LA oiling system for the rocker arms, we can modify the block for direct oiling from the lifter oil galley “A” up to the passage that leads to the heads “B”. Note: this is direct flow to the rocker shafts unlike the original intermittent flow. So a restrictor .060” – .080” may be required, usually at position “B”.

|