The process of picking out a cam is generally a very long process on the phone. The caller figures he has someone who will answer all of his questions, and listen to all his stories, and chat about each one of the questions. With the amount of calls we get we can't spend the time listening to their stories. And we have found that people will give us a more truthful answer if they have to write it down as to a verbal answer.

Read all of our "Wedge world tech" on the front of our web-site before you choose a cam to help you understand the most asked qustions.

Choosing a camshaft is probably the most important part of designing an engine combination, yet it can be the most confusing and frustrating part of your engine building experience. One of the problems is the confusing and contradictory way that cams are advertised and the way the specifications are listed. We ask lots of questions to get you the best cam for your application - help us help you with good answers.

There are some basic principles that are universal, apply to all brands of camshafts and must be understood.

- Camshaft size: Bigger or smaller is based on duration (how long the valve is open), not lift, more specifically duration @ 0.050" tappet lift. Advertised duration figures are not reliable numbers when trying to compare one brand to another for these reasons: first, advertised duration numbers include clearance ramps, which have little to no positive effect on performance. Second, advertised duration figures are not always checked at the same point with every brand, so the same cam can have several advertised duration figures depending on who or how it is checked. Third, using the duration @ 0.050" is a reliable way to compare cam size from one brand to the next, a good apples to apples comparison.

When selecting any camshaft for your engine/chassis combination, the size must be determined by the duration at .050" tappet (lifter) rise. Using a 1.5:1 rocker ratio this equals .075" valve lift. Any duration less than this has no effect on power.

- Understanding the duration at 0.050" may seem confusing but the important thing that must be remembered is: as the duration at 0.050" gets larger the camshaft gets larger and vise versa.

- The lower (or shorter) the duration at .050", the lower the RPM use, such as RVs, towing, stock engines, etc. As the duration at .050" increases, the power increases, however, the power band also moves up in the RPM range. This may require additional engine and chassis modifications to work best. One cam will not do everything well, you may have to make "tradeoffs". In other words, if you want to drag race with a cam that pulls at 6800 rpm, don't expect the engine to chug around on the street very comfortably.

- Cams have power bands, "sweet spots" or RPM ranges that they work best in. This power band or "sweet spot" does not mean that the cam will not work above or below this range. If, for example, the sweet spot is rated at 2000-5700 RPM, the engine will still produce power above 5700 RPM (at least ours will), but above 5700 RPM, the next larger cam will produce more power. By the same token, cams will produce power below their sweet spot, but the smaller cam will have more power there (see power curve graph).

- The cam size (duration at 0.050") determines where the "sweet spot" will be. All brands of cams of the same size will produce sweet spots in approximately the same rpm range.

- The "sweet spot" will be determined for the most part by the size (duration @ 0.050") of the intake lobe. Other factors such as the lobe separation angle, center line and exhaust lobes have some effect, but these are usually for custom cam installations.

- A change of approximately 5 duration @ 0.050" is considered one (1) size or step.

- The power the engine can develop in the "sweet spot" is determined for the most part by the rate-of-lift or how quickly the valve is kicked open. The quicker the better (ours are the quickest, like a roller cam, because they are ground to take maximum advantage of the large diameter .904" Mopar lifter "real Chrysler" cams).

- The best engine combination is when the sweet spots of all the components (camshaft, cylinder heads, intake manifold, carburetor size, compression ratio, headers and exhaust size) are in the same RPM range. For example, an RV torque cam with a large, single plane intake is a very poor combination.

- If you collect a very poor combination of "sweet spots" (also know as parts) and then try to pick a camshaft, you leave the cam supplier with an impossible job. We don't sell cams to people with really screwed up combinations unless they are willing to change some components.

- The first component you should pick when you build your engine is the camshaft, and that should be based on the power band or sweet spot you're looking for. Add the other parts to compliment it, not fight it. Check our list of questions on choosing a camshaft before you call. Unfortunately, most people build the engine first, then pick a cam and then expect the cam to "band-aid" the other parts to work.

- Our Basic Camshaft Guidelines list general guide lines for engine/chassis combinations. There are exceptions, but "tradeoffs" are involved. The actual power ranges will vary somewhat with the engine size, compression ratio (cylinder pressure) and the intake/heads ability to flow air. We need to know what you are going to use now, not future or past builds.

13. A mechanical cam will produce more power than a hydraulic cam of the same specs. However, we have some "stiff" hydraulic lifters that are the next best thing to a mechanical lifter.

We don't just want to sell you a cam. We want to sell you a cam that works for you. That is why we ask all of these pain in the butt questions! Do not use the answer "stock", as many "stock" ooptions were available. The better your answers, the better we can serve you. Answers like: But i could use a supercharger later on, etc. do not help! What do you need a cam for now?!

- What type of cam do you want? Flat Tappet or Roller, Hydraulic or Mechanical _______________________

- Engine size (Cubic Inch Displacement)

- Weight of vehicle, with driver.

- What category does you use fit? 1 through 8 (see below)

- Altitude where vehicle will be run.

- Desired ET or MPH (Specify 1/8 or 1/4 Mile)

- Present camshaft (duration @ .050", Lobe separation angle, lift etc...)

- Final gear ratio

- Stall speed of torque converter

- Tire height

- Fuel type/Octane

- Cylinder Cranking Pressure

- Iron or aluminum heads

- Measured Compression Ratio

- Intake manifold

- Header type and size

- Carburetor size

- Rocker arm type and ratio

- Will power adders be used? (N.O.S., turbo, supercharger etc...)

- Do you intend on using a tuner (Factory 5.2/5.9 F.I. Magnum engines only)

- Cylinder head airflow numbers (Fill out chart below)

| Lift |

Intake |

Exhaust |

| .200" |

|

|

| .300" |

|

|

| .400" |

|

|

| .500" |

|

|

| .600" |

|

|

Cam Categories: (See below for more detailed information)

1. Towing & mileage

2. Light towing, cruiser, street, stock replacement

3. Whiplash

4. Hot Resto Cruiser

5. Hot Street / 10% Strip

6. Street / Strip 50/50

7. 90% Strip / 10% Street

8. Race Only

Note: Please try to use numbers or measurements such as: 1600 RPM stall, not "stock stall" because Chrysler provided many size varieties of "stock" parts.

Remember, the more information you provide, the more accurate the recommendation. We can move the lobe separation angles and mix/match lobes for very special applications. If you follow these instructions, in most cases, you will choose the correct camshaft.

Compression Ratio:

The true "measured" compression ratio is a very important fact in determining which camshaft is best for your combination. "Stock" compression in a Mopar can run from 7.5:1 to 10.5:1, so, using "stock" is a good way to make a bad mistake. Using the pistons advertised compression ratio can be very misleading too. The compression ratio is a function of cylinder head volume in c.c's, ("stock" can vary 6 to 8 c.c.'s) deck height, gasket thickness and piston deck height. In situations where you can't check these dimensions we suggest you check your cylinder cranking pressure. In order to get this number, remove all 8 spark plugs. Do not squirt oil into the cylinders. be sure your battery is fully charged and stays fully charged (keep a charge hooked to it). Then crank it over and take cranking pressure readings on at least 2 or 3 cylinders.

Why do we ask for all of this knit picky information? Why don't we just pick a cam like everyone else does and just sell it to you? Because we don't want to be like everyone else. We really care that you get what you need and we are not happy unless you are making a lot of power.

Cylinder pressure note:

The cylinder pressure is a result of 5 things, the static compression ratio, cylinder head material (iron or aluminum), the closing point of the intake lobe, the altitude of operation of the engine and the final displacement of the engine. When using 93 octane gasoline, build your engine for 165psi cylinder pressure with iron heads. Whenusing aluminum heads aim for 195 psi cylinder pressure.This is generally the maximum safe pressure and power without detonation or odd spark curves. As the camshaft gets larger (duration at .050" tappet lift), the static compression ratio must be raised to maintain the cylinder pressure. For maximum power in your engine, request our computer generated cylinder pressures/static compression ratio numbers when ordering your Real Chrysler Camshaft.

Mopar Performance camshaft note:

When replacing a Mopar Performance camshaft with a Hughes Engines "real" Chrysler camshaft, use one that is 5º to 7º smaller at .050" tappet lift for increased power in all RPM ranges.

| The Power Curve |

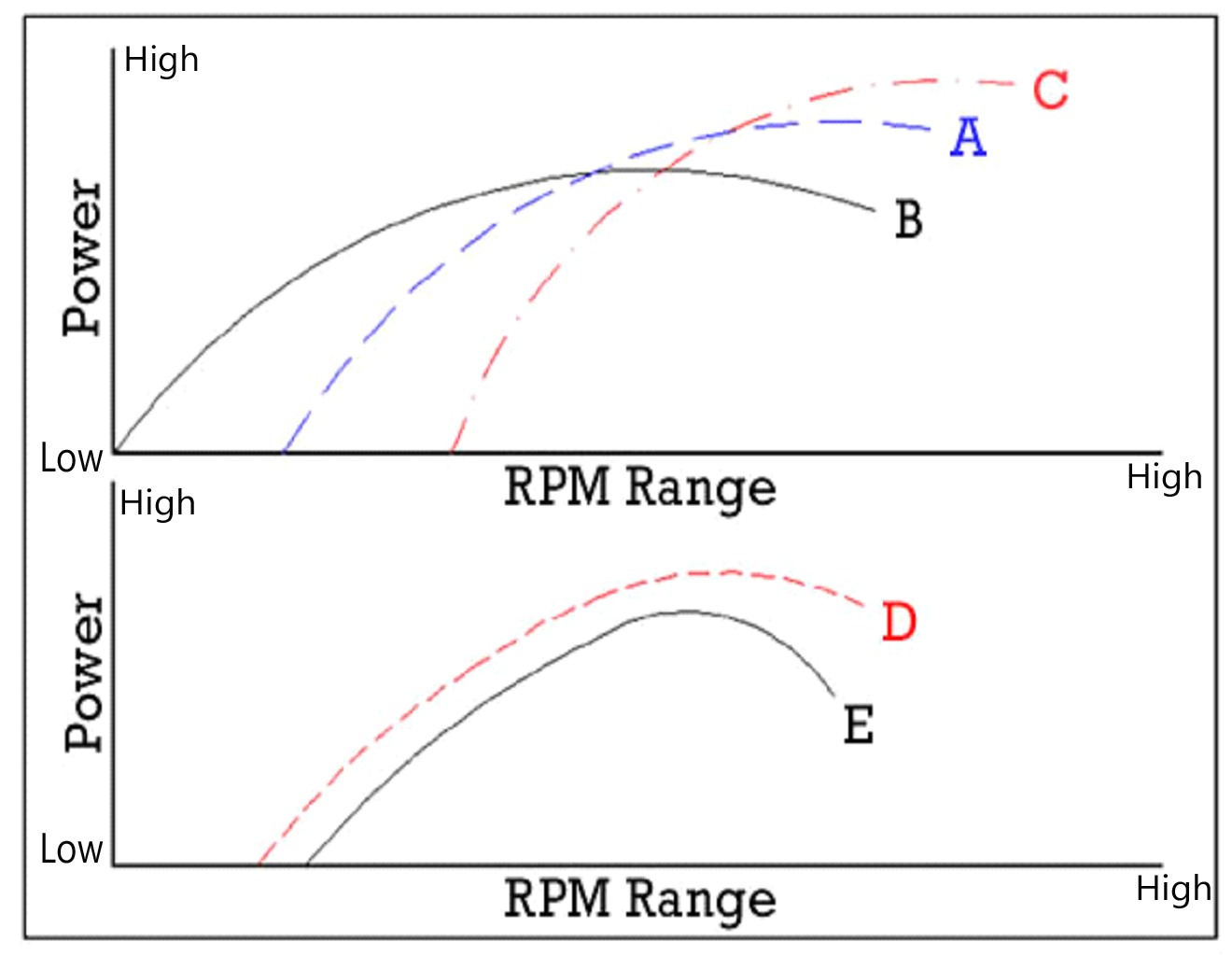

The graph below describes what you should expect when you build an engine for a specific power range. If the engine breathing combination (cam, carb, intake, heads, headers and compression ratio) are properly matched, the duration at .050" on the intake lobe will generally dictate where the power curve will occur. This way you can compare the potential results with cams from various sources. Note that as the engine power increases, the power curve will become narrower and steeper. It will also move up in the RPM scale.

If your combination develops power in the "A" curve and you choose a smaller (duration @ .050") camshaft, you can expect to see your power curve move to the left, the "B" curve. Notice that the "B" curve is wider, but has a lower peak power. If you choose a larger (duration @ .050") camshaft, your power curve will move to the right, the "C" curve. This curve is narrower, but has higher peak power. If you pick a camshaft with the same or very close (2° to 3° duration @ .050") your power curve will be approximately the same. HOWEVER, when installing a HUGHES ENGINES "real" CHRYSLER CAMSHAFT you can expect to see the maximum power increase and the power curve widen. With a Hughes Engines camshaft (curve "D"), the power will start sooner and pull longer, resulting in more peak power. The RPM location of the peak power will remain about the same as long as the duration at .050" on the intake lobe remains the same (curve "D" vs. curve "E")

|

|

| Advancing and Retarding the Camshaft |

| Advancing the camshaft, (a lower intake lobe center line number, 104 vs.108 for example) will tend to start the power band sooner in the RPM range. It will also increase the cylinder pressure. Retarding the camshaft (a higher intake lobe centerline number 108 vs. 104) will generally start the power band later in the RPM range and decrease the cylinder pressure. However, these rules are not absolute. Depending on the engine combination, the opposite results can occur. Call for details with your specific combination. |

| A WARNING on Computer Engine Designing and Testing |

| We have many people call us requesting timing figures to enter in their computer dyno programs. We are happy to supply these figures. However, we will only supply them at .050" tappet lift because we do not consider the advertised duration figures to be relevant. Advertised duration is not checked at the same point with every manufacturer. A lot of lower priced computer dyno programs will not accept duration at .050" tappet lift figures. Most of these simulation programs are not designed with Mopar engine features, such as quench heights, longer rods, lifter diameter, etc. Therefore, the results from these types of programs are misleading. The better programs (and there are very good ones) naturally cost considerably more. If the program you are using doesnt ask much (such as flow figures, quench heights, rod lengths, cam timing at .050", etc.), do not expect good indications of the power potential.. |

| Group |

Characteristics |

Suggested (not required) Upgrades |

1

Towing / Mileage |

Smooth idle, good vacuum, stronger low end power, more torque.Helps low compression engines. |

Recurved distributor, upgraded ignition, dual exhaust or headers, 4 bbl intake. 8 or 9:1 compression. |

2

Light towing / Mild Street Performance |

Nearly stock idle & vacuum, strong low end & more mid-range than the Type 1. Mileage near stock. Slight idle sound. |

Recurved distributor, upgraded ignition, Dual exhaust or headers, low rise 4 bbl intake, 3.23+ rear gear, 650cfmcfm 4 bbl carb. 9:1with iron heads. |

3

Hot Street |

Hot Resto, Cruiser, Hot Street Noticable idle, reduced vacuum, very strong mid-range and top end. |

Performance distributor, headers, high rise dual plane intake, 670cfm+ carb on small blocks and 750cfm+ on big blocks. 2,600+ stall converter, 3.55+ gear, head work, true ratio roller rockers, 9.5:1 compression with iron heads or 10.5:1 with aluminum heads. |

4

Hot Street / Some Strip |

Hot Street / Some Strip

Agressive idle, low vacuum, strong cam. Marginal for street, serious strip use. |

High Performance distributor & ignition system, headers, single plane intake, 750cfm+ carb for small blocks and 800cfm+ for big blocks. 3,200+ stall, 3.90+ rear gear, ported heads and intake, true ratio roller rockers. Blended or race gas. 10.5:1+ compression with iron heads or 11.5:1 with aluminum heads |

5

Street / Strip |

Street/Strip

50/50

Still on Pump Gas

Serious Street Performance |

Good ignition, headers, high rise dual plane intake, vacuum secondary carburetor, 3.90+ gear, 3200+ stall, true ratio roller rockers, ported heads, ported intake or deep port matched intake. 11:1 CR w/ aluminum heads depending on cam |

6

Strip/Street |

90% Strip/ 10% Street

Race Gas |

Good ignition, headers, high rise single plane intake, mechanical secondary carburetor, 3.90+ gear, 3200+ stall, true ratio roller rockers, ported heads, ported intake or deep port matched intake. 12:1 CR. Mechanical cams do not like the street. |

|

7

Race Only

|

Race Only |

Good ignition, headers, single plane intake, mechanical secondary carburetor, 4.10 gear, 3500 stall, true ratio roller rockers, ported heads and intake. 13:1+ CR |

|

8

Whiplash

|

These cams have a very aggressive idle and explosive power right off idle. This cam will pull hard to 5000/5500 rpm. Vacuum will be low (9" - 11") |

Recurved distributor, HP ignition, dual exhaust or headers, 4bbl low rise type manifold. 7-8.5:1 compression with iron heads in small blocks, 7.5 to 8.5:1 in big blocks. Small blocks with aluminum heads can be as high as 9.25:1 and big blocks 10.25:1. |

|

9

Stroker Engines

|

Strokers increase the displacement of an engine which in turn makes the cam act smaller. |

Generally if you pick a cam 2 sizes larger than the characteristics you are looking for, it will be a good choice. If you are confused, please call us. |

|

10

6 Pack Resto

|

Our 6 pack replacement cams have the same overlap as the OEM 6 pack, same duration @ .050" on the intake with a reduced exhaust duration. We have more area under the curve for better breathing. |

Recurved distributor and upgraded ignition, headers, hot street OEM heads, designed for use with HP cast iron exhaust manifolds. |

|