#2---INDY Heads & Intakes | 1/4/2014

David Hughes |

|

Revised 10/2015

|

|

We are now a Warehouse Distributor (WD) for INDY cylinder heads.

As you read through this article you will notice some of the words appear in orange or in blue. These are links to the product they are describing. Click on the colored words and it will open a new browser window where you can view the prioduct without losing your place in the tech article. When you are done looking at the product or you have added it to your cart simply close out the window and you can continue where you left off in the tech article.

The words "stock replacement" to us, and to you, should imply that a head can use all stock parts. Not that you would want to run them, but the parts would fit and work on them, such as the iron intake and exhaust manifolds, OEM stamped rockers and stock valve covers. Well they all do fit, and no, we did not try to run them! Also, it is a head that can be ported to flow with many of the "race" heads on the market that have stock valve locations (and maybe even better --- stay tuned).

|

|

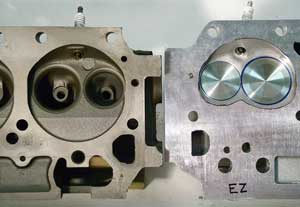

Big Block Indy EZ or EZ-1 exhaust side

|

We can supply our customers with the complete Indy line up of Mopar wedge, Hemi and AMC heads, blocks and manifolds. The constant demand by our customers for more power has lead us to the Indy line and we are very pleased to offer their products. If you want to run with the big dogs you gotta get off the porch, so we're "getting off the porch".

|

Due to other manufacturers inability to provide an adequate supply of heads and the high demand for just such a head, we needed a product to fill the void, and we have been successful at doing just that, and more, with the HUG 4950 head.

Some of the EZ advantages are:

1. Availability. If we don't have what you want we are 1 shipping day from INDY.

2. The assembled heads with the pushrods, valley cover, head bolts and intake gaskets cost the customer less than when purchased separately.

3. Finished quality. This allows us to deliver a finished head for less.

4. Smaller combustion chambers, in other words, more compression.

5. A wide range of options including CNC porting.

6. Many accessories. For example, large port intake manifolds in several configurations as well as cast, aluminum valve covers.

The Indy heads have raised intake ports, and 0.250" longer valves which allows them to flow more air, especially when ported properly. Unlike previous Indy heads, the EZ heads oil the rockers thru the heads just like the stock heads and therefore do not require any external oil lines.

The EZ's have 2.19" intakes and 1.810" exhaust valves with 11/32" stems which are 0.250" longer than stock. You will need longer push rods, which come with the kit. Kit? What kit? The INDY head is available with a basic kit that contains the longer, cut-to-length push rods which are 0.080" wall, Manley head bolts, a cast intake valley cover and intake gaskets.

|

The head with the "Kit". The pushrods and head bolts are shown for 1 head, but you'll get them all.

The head with the "Kit". The pushrods and head bolts are shown for 1 head, but you'll get them all.

|

The EZ's come with standard 440 intake port openings or Max-Wedge (M/W) size. The base head is a 440EZ and it has the 440 port opening opened up to gasket size. In the right hand photo below, the head on the bottom is a stock '906. The M/W heads (P/N HUG 4950) can be supplied with 3 different port types and sizes. The base 440 EZ-1 is the same as 440 EZ head only with a CNC M/W port opening. Next in line is a fully CNC'ed head, including the combustion chamber, with a 295cc port volume. Finally there is a fully CNC ported head with a 325cc port volume. The 295cc port head uses standard, Big Block offset rockers; the 325cc port requires special INDY 0.800" over rockers, also available from us.

|

The EZ with the 440 port opening on the left. The EZ-1

The EZ with the 440 port opening on the left. The EZ-1

with the CNC Max Wedge (M/W) port opening on the right. |

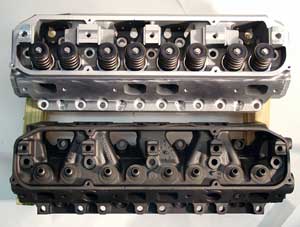

The EZ on the top with the intake port opening compared the OEM iron head on the bottom. The EZ ports appear larger because they are out to gasket size, out of the box.

The EZ on the top with the intake port opening compared the OEM iron head on the bottom. The EZ ports appear larger because they are out to gasket size, out of the box. |

#14---Secrets of the Indy EZ head & CNC Super Prep work.

We are especially interested in the 440EZ with standard port openings. They will match the requirements of a great majority of our Big Block customers. They have a very nice, small volume exhaust port that accepts standard 440 headers, (they are not high port) and will flow the numbers we want with a lot of velocity.

|

The EZ on the top again, appears to have smaller exhaust port openings---and they do!

The EZ on the top again, appears to have smaller exhaust port openings---and they do!

|

|

The photo above shows the difference between the exhaust ports. The EZ's have what could be called an inverted "D" shape and they are actually a smaller, very high velocity port, which accepts standard headers and gaskets. The bolt holes are closed so the studs don't need sealer. The bottom of the port is about 0.100" higher than the '906 but the top is only about 0.080" higher. The exhaust gasket surface like all aluminum heads is extended out about 0.120". The heads can also be supplied with a huge CNC exhaust port for users of big shots of nitrous oxide. (N2O)

|

|

The next photo shows the difference between the smaller, 78cc, high swirl, heart shaped combustion chamber of the EZ ,on right, versus the stock '906 on the left. We can also offer the chamber CNC'ed out to 82cc's . The valves are 2.19" and 1.81" diameter, both with 11/32" stems and they are 0.250" longer than stock. The longer valves allow the port bowl to be longer/deeper, which straightens out to flow after the short turn. This allows more air/fuel to enter the combustion chamber, and even the "chatters" know what that means. The angled plug location and position in the chamber are clear here too.

|

The combustion chamber differences are dramatic.

The combustion chamber differences are dramatic.

|

|

The photos below illustrates several things. The valve cover gasket surface is milled for good sealing, the rocker saddle bosses are extremely beefy and the plugs are angled like all of the other aluminum heads for Big Blocks and at the same angle. There is not a lot of room here to things to be much different than everyone else. Also, from here you can see that the ends of the heads are squared-off, so painting them won't hide anything.

|

In this overhead view along with photos above, show that the Indy valve cover surface is smoother and more substantial without a lot of cavities that remove metal and strength.

In this overhead view along with photos above, show that the Indy valve cover surface is smoother and more substantial without a lot of cavities that remove metal and strength. |

The right end of the head, when viewed from the exhaust side, is drilled like the stockers, and has an Indy logo too!

The right end of the head, when viewed from the exhaust side, is drilled like the stockers, and has an Indy logo too! |

Yes, we will be porting these new EZ heads, some preliminary tests show us that these heads have some terrific potential, possibly beyond what is currently available in CNC'ed form and with smaller port volumes (how does 350cfm at 0.650" lift sound, it sounds gooood to me too) The goal here will again be to get the flow up very quickly and not be so concerned with the maximum flow possible at the extremely high lift points. We are test porting them as this is being written, June 2005.

As a side note, we picked up our first order at the Indy plant, visited with their staff and toured the facility. We were impressed with the size of their operation and the fact that their business is more of a manufacturing facility than and end user supply source. Russ, one of the owners, said as much in that they are more oriented toward servicing dealers than individuals looking for help building their engines. This fact may explain the reason that some callers don't always get the personal service they are looking for when the call Indy direct. That is our strength, give us a call and we will help you get the Indy parts you need!

|