|

|

#2---Main Bearing Stud Girdles 04/23/2007 | 4/23/2013 |

Main bearing girdles were first used on supercharged Small Block Chevy's in the early 60's. When the heavy-duty 4 bolt blocks became available they disappeared. The 5.0 Ford started splitting down the middle about 10 years ago and the main bearing girdles again made their appearance. All of the new power producing parts such as strokers, high flow heads, manifolds, and camshafts available today severely over stress the stock Mopar blocks. The 'good' cross-bolted factory Big Blocks and the 4-bolt 340 blocks are in limited supply at best, or nonexistent. This leaves you with 2 options: our main girdles or - "that can't be good" - Bubba!

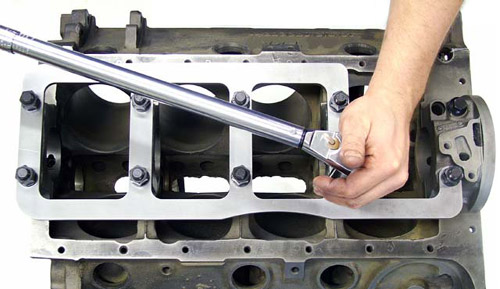

The beauty of these kits is that you can use the original main caps, which will only require line-honing. This drastically reduces the cost of the job and gives better support than other methods to boot - a true win-win situation.

The main bearing girdles are used to tie the main bearing caps and bulkheads together, thereby stiffening the block lower-end and increasing crankshaft support. Our stud girdle is designed to reduce fore and aft and lateral block movement (that means front-to-rear and side-to-side for the chatters). We are not trying to prevent bending of the block with the girdle. The thickness of the girdle has very little to do with its strength. Its strength lies in its width rather than its thickness. For the vertical strength (thickness) to be a factor, the plate would need to be 1.5" to 2" thick and have the caps as an integral part of the girdle. Many newer OEM engines are made this way and that is a good design, which cannot be duplicated with a flat plate. In addition, if the plate is too thick, it makes oil pan removal more difficult in the chassis.

When the engine is running, especially under highly loaded conditions, the crankshaft is being twisted back and forth trying to move the main caps and bulkheads along with it. This crankshaft twisting is the reason for needing the harmonic damper. When the power output (twisting) becomes great enough the main caps will move "walk" against the block causing fretting (micro-welding). If this continues long or hard enough, the caps and/or main bulkhead can crack. Worst-case scenario: the block will split up through the cam bores.

Our girdles provide additional support points below the crankshaft and tie all the caps together substantially reducing any possibility of flexing or twisting. Testing (pre and post girdle) has shown power increases in engines with severe twisting (binding) situations and longer component life with the girdle installed.

The small block kit can be bolted on with no machine work required. There is also an option of machining the caps for increased clamping area. Instructions for both applications are included. The big block girdle ties the main studs into the pan studs and block skirt area, too, and there is no machine work required.

All kits are complete with studs, shims, spacers and nuts and, as always, our real world, easy-to-follow instructions. The kits are supplied with studs for their superior clamping ability. When installing studs, the block must be line honed, unless it was previously line honed with studs. Using longer studs will not have an effect.

Wow! When it rains it pours! There are more people making big block main bearing stud girdles everyday. Some of them are partial kits with no instructions and no one to call for help and others are very elaborate and could easily be considered overkill.

What we are all dealing with is a stock block that has many weak areas. The main cap and bulkhead areas are ones that show up first and can be strengthened by using our main bearing stud girdle kit. When we developed our girdle we were seeing cap walk when the horsepower reached the 600HP area. The longer stroke engines only exacerbate this situation. (For you "chatters" exacerbate means "to make the situation worse".)

Our goal was to have a system that would allow the stock blocks to live at 907HP, for obvious reasons. We have customers who have exceeded this goal by 10% or more. Therefore we our confident that our system is more than adequate when dealing with a stock block. We do not suggest or recommend using other than stock main caps. We do not feel the extra expense and machine work is worth it. Ours, and our customer's success with our design has proven this point. The caps are not the problem.

The stock blocks have other weak areas that cannot be addressed by making the main caps & girdle any different than what we offer. There also seems to be a misunderstanding by some girdle suppliers as to exactly how our kit is designed. Just because they claim that their kit is exactly like ours don't be fooled! They aren't.

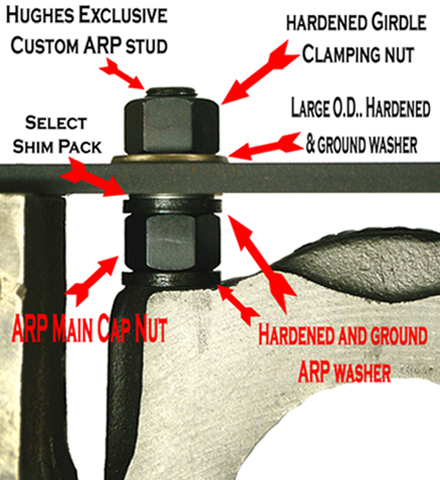

We use clamping bolts on the main caps AND the girdle. (see photo below)

Next we use selected shim packs between the main cap nut and the girdle. Then a second nut is used to clamp the girdle to the stud. We do not stack up washers to fill the space between the main cap the girdle. When using our system there is no distortion of the girdle.

What about attaching the #5 main cap to the girdle? This looks like it would be easy to do.... that is until you try to put the oil pan on. There is not room unless you want to play "Jesse James" (of Monster Garage fame) on your pan and even then it is a very tight fit. We looked into putting a smaller stud, like the oil pan studs, in the #5 cap but knew our customers would see that as a ploy to "claim" that we had clamped to the rear studs when in fact it would have been a less than sincere effort. And even then you must ask yourself if it is really worth the extra work if the girdles support strength is already exceeding 907HP...which it is. You can put lipstick on a pig but it is still a pig.

If the prototype of our current design had not been successful at the original designed goal of 907HP we had a "Plan B" to strengthen and stiffen the bottom end of the block even more. Since this was not needed we didn't pursue it. Just as a point of interest... these stiffening techniques did not have anything to do with the main caps themselves or making the girdles any thicker!

Be warned when others try to copy or modify our original design, they don't give you everything. One of the strengths of our kit is is in the fact that we are clamping the cap to the block with one nut and the girdle to the cap with another nut. We are not relying on one nut to try and hold it all together. Others cannot do this because they do not have access to our custom made ARP main studs. Remember, ours are running at over 907HP with stock caps and no sign of cap walk. This is the best complete kit at the best price. Some of the others may be smooth talkers but they are poor copycats.

|

|

| | Home | Phone: 309-745-9558 | Email: information@hughesengines.com |