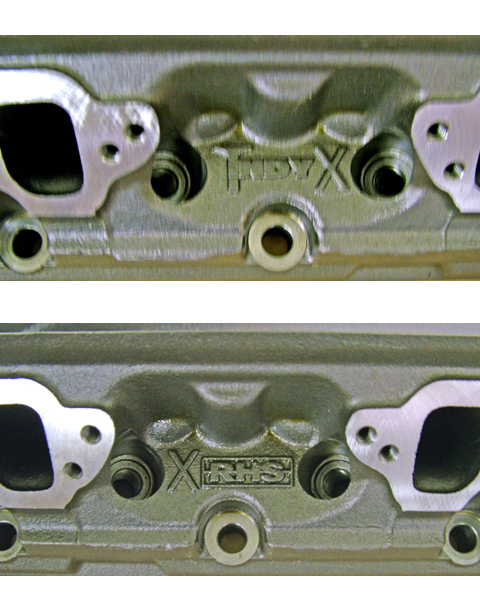

The INDY/RHS small blocks are available in both the LA style (La-X) and the Magnum style (Ma-X),

and what follows are some points of interest that our customers may appreciate knowing about.

The La-X head is the one we get the most calls on so we will show it and point out differences in the Ma-X heads as they come up.

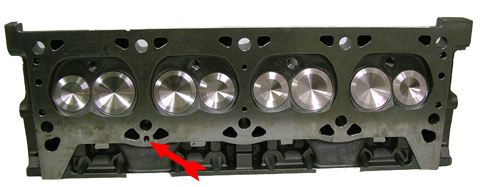

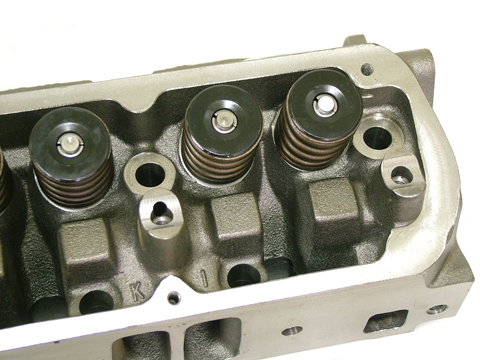

This is the La-X head. The oil passage for the rocker arms is pointed out by the red arrow.

Note that this head must be used on a block that has this passage, like all LA blocks and

some very early Magnum blocks.

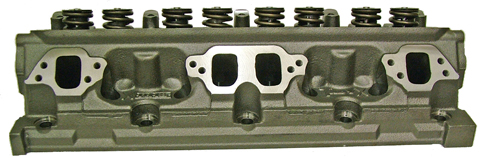

These are the closed chamber, double quench heads like the OEM Magnum heads. The

chambers are 62cc. The oil passage pointed out in the photo is only on the La-X head.

Other than that, the Ma-X head is the same.

Both heads have the double bolt pattern on the exhaust. The narrow, standard LA pattern

and the wider W2 pattern are both drilled, tapped ready to use.

The valve cover mounting surface is drilled for the 5 bolt cover on the La-X head. The Ma-X

heads are set up for the Magnum style 10 bolt valve covers. Either valve cover will work on either head.

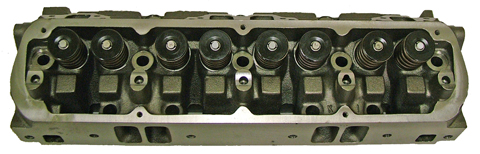

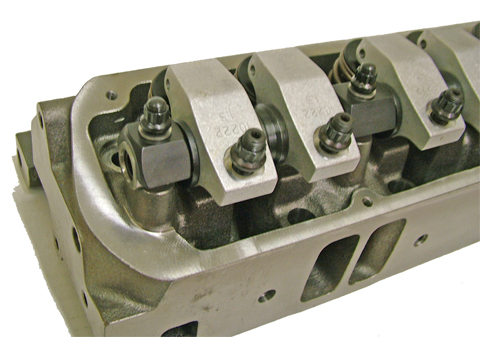

This is a close up of the La-X head showing both the cast-in rocker pedestals as well as the

LA style valve cover bolt pattern. The intake opening is 2.175" X 1.140" which is about half way

in-between LA and Magnum port sizes. The intake manifold bolt angle is LA stle on LA heads.

This is a close up showing the rocker shaft oil passage. This head has the LA intake bolt

pattern and angle and, the standard 5/16" bolt size . The intake pushrod tunnels will need to be cleranced when using a flat tappet cam.

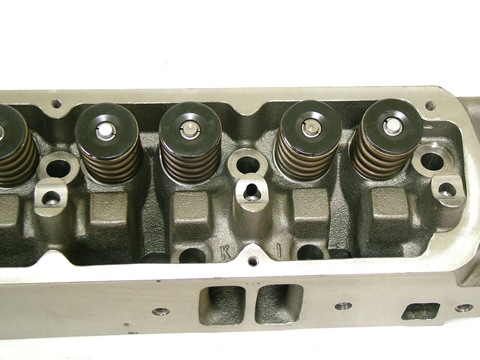

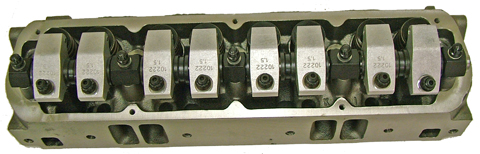

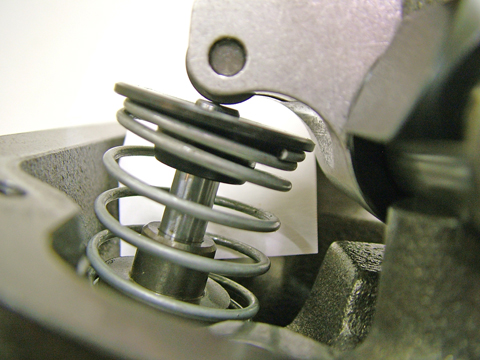

The big question, "How about rocker arms?". Will the Hughes Engines "real" Chrysler rockers fit?

The answer is YES! You can see them in the photo above installed with our billet hold-down kit.

These are the early style rockers without the oil channels on top.

Just a little closer view of the rockers(still the early style) and hold-downs installed on the LaX head.

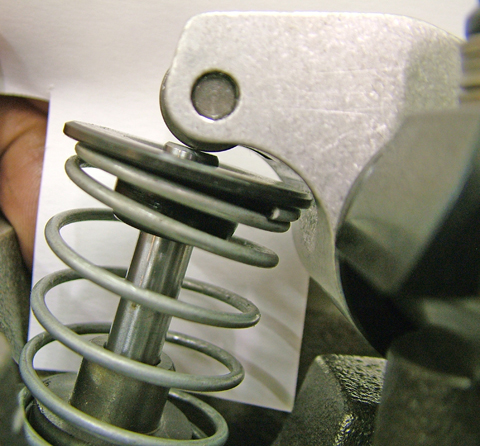

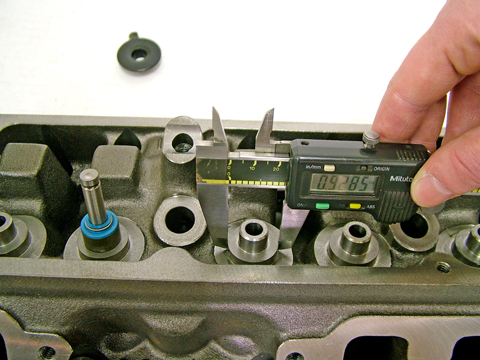

On the heads we checked the tallest spring installed height we could get was 1.627".

Note: That was achieved using this tall retainer in which the stem barely clears the

retainer, about .040". Wehave safely cut the the spring pockets (bases) up to

.130" which would result in a 1.800" installed height. What this boils down to is that

for most applications you will need to have the spring pockets cut. Let us know

what you need and we can do it.

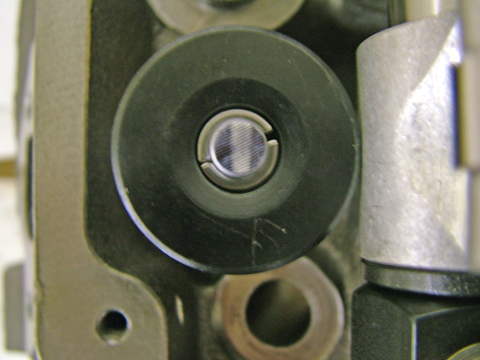

Rocker arm geometry...valve closed....roller tip is biased slightly toward the shaft...NICE!!

Shown now at .350" lift. The roller is over center. Oh yeah! Very nice!

Now at .650" lift. The roller is back to the same position it was in when the valve was closed

on the seat. As Chris Matthews said when he heard Obama speak, "I feel a thrill go up my leg"!

This kind of lift can only achieved with a test spring. It was done for demonstration purposes only.

PERFECT WIPE PATTERN!

The spring bases are cut to fit large O.D. springs, however, with both available head types,

the more common double springs, like our 1129, the spring centering boss will have to be cut

to a smaller diameter. As show above, it starts at .928". A beehive spring kit (P/N 1286K) will

drop on with no machine work required.

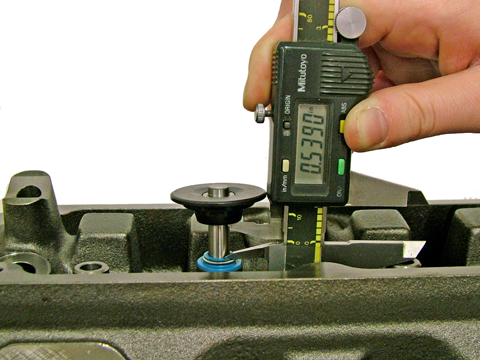

The maximum safe lift at the valve will be about .530" on the OEM Magnum heads. Both

Indy and EQ heads have the guides shortened and we have used cams with .650" valve lift.

These heads would use our #3806 valve stem seal. Remove thegarter spring on the seals.

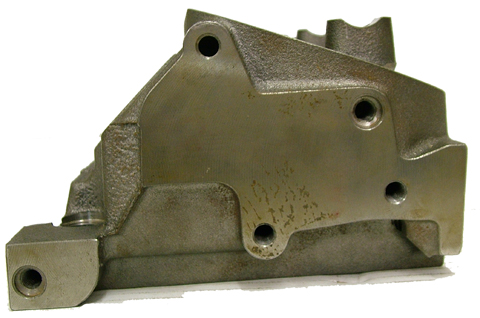

The heads are set up with accessory holes to fit the needs of most LA or Magnum installations.

The way these heads are logo'd up nobody is going to mistake them for an old set of

junkyard heads. NOTE: These logos can be removd so the heads look "stock".

The boxes have nice hand holds for carrying, which is important when you are moving around

a 58 pound head!

In summary these heads appear to be a very nice piece with a lot of potential.

|