|

|

#2---Magnum & LA Heads | 1/15/2021

David Hughes |

|

07/07/2005

With the availability of our lower cost stroker kits for the Small Blocks, we are seeing more interest in Small Block build-ups and that is especially true in the cylinder head area.

As you read through this article you will notice some of the words appear in orange. These are links to the product they are describing. Click on the orange colored words and it will open a new browser window where you can view the product without losing your place in the tech article. When you are done looking at the product or you have added it to your cart simply close out the window and you can continue where you left off in the tech article.

Two of the bigger changes are: 1. The fact that Chrysler no longer services (produces or sells) the old Small Block LA heads, and 2, The introduction of the Edelbrock Magnum aluminum heads.

These two moves mean that: LA iron head's availability will get much worse than it already is, and the practice of retro-fitting magnum heads to older LA blocks will be more common, and the parts and modifications to magnum heads will increase. At Hughes Engines we have you covered in all of these areas.

First we'll look at the Magnum heads. There are 5 types of magnum heads available.

1. The standard head that was OEM on the trucks from 1992 to 2004, they are iron, casting numbers '466, '671, '714.

|

Stock magnum head as installed by the factory

Stock magnum head as installed by the factory

|

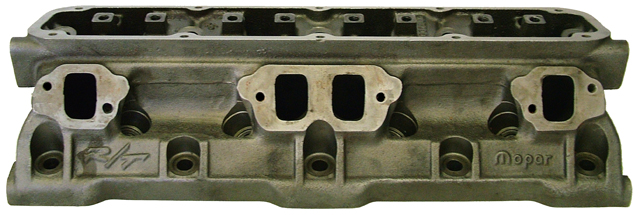

| 2. The R/T heads are an over-the-counter part from Mopar Performance, NOT an OEM head on R/T trucks as believed by wishful R/T truck owners. These are also iron, a lot of iron. They are heavy! |

The R/T head, note the raised R/T emblem and Mopar cast on the head

|

3. The factory aluminum, this head, in our opinion, was designed by a person or group that had no idea of what they were doing or how to do it, and we will waste no more of your time or our web site discussing it!

|

4. The Edelbrock Magnum aluminum heads. Note: The LA heads can be adapted to the Magnum blocks if the block is drilled to feed oil to the heads, some of the early ones were. We bring this up because it is a common question, but ill advised 99% of the time.

|

Edelbrock Magnum Head

Edelbrock Magnum Head

5. The new Heavy Duty Magnum head may well be the ultimate replacement head for most Magnum applications. We are recommending these heads for the L.A. engines that require iron heads due to their strength, durability, and flow characteristics. Click here to view our tech article ( #8---La-X and Ma-X Iron Small Block Heads). You will be impressed! (Added as of 12/12/2012).

The Magnum head is adapted fairly easily to the older LA block. Many parts can be mixed and matched between the two head and block combinations successfully. When adapting the Magnum heads to the older LA blocks you will need to be aware of the following:

The Magnum blocks feed oil to the rocker arms and heads through the lifters and pushrods. We can supply the oil-thru lifters for any combination you need, and the parts will service both V6 and V8 engines.

HUG 5001 standard hydraulic flat tappet

HUG 5003 racing hydraulic flat tappet

HUG 5012 solid mechanical tappet

HUG 5006 OEM type hydraulic roller

|

Magnum lifters reading from left to right

|

Oil thru pushrods are available in either cut-to-length kit, assembled, or even adjustable, to fit any application from flat tappet to roller. Some of you may have been uncomfortable with adjustable pushrods fearing that they were a low strength, low cost way to get around buying adjustable rockers. Check this out, most of the nostalgia top fuel cars and others using the old 354/392 Hemi's use adjustable pushrods because of the cost of roller rockers for them, and they "get by" very well and they do it quickly. Speaking of them, you need to check out a "CackleFest" which features these old fuelers and their adjustable pushrods at a drag strip near you, they'll make the hair stand up on the back of your neck.

|

Both ends of the assembled

pushrods will look like this

|

The adjustable end of

the oil-thru push rod

|

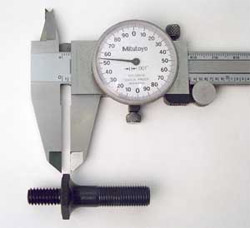

The intake manifold bolts in the Magnums are smaller, 5/16", and at a more vertical angle than the LA engines. If you are buying your heads from us and you need an LA bolt pattern order part number LADRL. In the iron heads you will have both patterns available.

|

This head has been drilled for both bolt patterns

This head has been drilled for both bolt patterns

At the present only the Edelbrock RPM air gap manifold (P/N EDE 7577) is available with the Magnum bolt pattern, and it matches the Magnum ports very well. The availability of the Mopar Performance 4 barrel manifolds for Magnums is spotty at best. This drives the demand for adapting the more available LA intakes to the Magnums.

|

Note the vertical bolt holes in this Edelbrock intake

|

The Magnum ports are not exactly the same size and shape as the LA ports. The former are shorter and wider than the latter. This is not a big difference and in many cases not a big performance loss, but to get a perfect match will require some grinding. If you order your heads from us and want them opened to LA size, order a port match part number I320.

|

The LA port ,on the top, is taller

|

The Magnum head bolts have two lengths. The long inner bolts are about 2 threads longer than the LA's and the outer row are the same length. ARP head bolts for the iron Magnum heads are P/N ARP 144-3604, for the Edelbrock aluminum heads use P/N ARP 144-3605. All of the LA headers and exhaust manifolds will bolt-up and seal properly on the Magnum heads.

|

The ARP head bolts and washers for the Magnum heads

The ARP head bolts and washers for the Magnum heads

|

The biggest issue when swapping to the Magnum head is the rocker arm issue. First of all the stock ratio on the Magnums is 1.6:1, NOT 1.5.1 like the LA's. Don't get sold a set of 1.6:1's as a high lift or a set of 1.5:1 as a stock ratio. How many times must you be told to stay away from those Chevy places?

For the budget racer or when the rules dictate OEM rocker arms, as many oval track rules do, we have oil-thru adjustable pushrods that will live with at least 350lbs over the nose spring pressure when properly installed. They will work with solid and hydraulic rollers too!

|

Adjustable oil thru pushrod. We can custom

Adjustable oil thru pushrod. We can custom

make them for special lengths too!

|

When using stock rockers in racing applications, or with more than 280lbs over the nose pressure, the rocker must be modified to force the oil flow from the pushrod down to the trunion so it is adequately lubricated. This information is supplied with the pushrods if you request it.

For those of you who can use a roller tip rocker, we have what you need for V6 or V8's. Actually they are the same rockers and pushrods we use on the Edelbrock heads only with the iron head kits we include the studs and guide plates. There are 5 different guide plates that we are aware of at this time, available for the Magnums, and there are problems with all of them.

|

The rockers installed on a Magnum head

|

When the rockers are stud mounted, the guide plate working thru the push rod locates the roller tip correctly over the valve tip and prevents the rocker from turning on the stud. The spacing of the push rod slots in the guide plate is very critical. If the spacing is not correct then the rockers will "toe in or toe out".

|

The pushrod slots are too far apart causing the rockers to toe-in, this is a bad thing

|

Here the slots for the pushrods are too close together, causing the rockers to toe-out. Look for these kits on other, less informed web sites. |

|

The next problem is the stud, the hex on the stud will need to be very short compared to the more commonly available Chevy type studs. The taller hex will drag across the bottom of the rocker body. Now to those of you new to the stud rocker set-up (or live in chat rooms and you know who you are) it will appear that if you use a longer pushrod you can raise the rocker and eliminate the problem --- wrong bow-tie breath! What you will do is to move the roll pattern of the roller tip out to (or off) the edge of the valve tip and accelerate valve stem and valve guide wear, or worse! This geometry problem is especially critical on the Magnums because of their small, 8mm stems. We will encounter this same problem again with the extra thick guide plates.

|

Guess which stud is from the Chevy, also available on other

Guess which stud is from the Chevy, also available on other

web sites. Our P/N HUG 7600 is the correct one on the right

|

You will need a set of pushrod guide plates and a set of hardened pushrods to work with them. The stock pushrods may be the proper length in some cases, but the guide plates will eat them up before you get backed out of the garage. Get the hardened ones. Because of the plethora of lifter lengths available to us with Magnum heads, there are several lengths of pushrods possible. We can supply what you need or make custom lengths as usual.

|

The part number for our 1.6:1 rockers is 1536-16 for V8s and 1536-12 for the V6s. This includes the poly lock adjusting nuts. The rockers and the poly locks are 3/8". We see no need, at this time, for 7/16" studs on either the top or the bottom of the stud. Our P/N HUG 7600 is for a stud that is 5/16" on the bottom and 3/8" on the top. The guide plates for the 5/16" pushrods are P/N EDE 9662. A note of caution on the guide plates, some of them are thicker than others and they may cause the hex on the stud to drag against the rocker. Clearance in this area is tight when the geometry is correct!

|

Fully rollerized 1.6:1 for 3/8" studs

|

Thin hex 5/16"-3/8" stud |

The correct guide plate

|

Part number 1536-16 will be a complete 1.6:1 rocker arm drop-on kit, requiring no machine work, the kit could be installed with only the rocker covers needing to be removed. The stock rocker covers will need the baffle modified to clear this set-up. Instructions are included with the kit. This is the perfect kit for the daily driven trucks; you should be able do the changeover in an afternoon.

|

Kit for one cylinder shown

|

We believe the 5/16" stud is strong enough for all hydraulic roller cam with lifts up to 0.580". The heads can be removed, drilled and tapped for the larger studs. Here again you will need one with a thinner hex to clear the rocker as mentioned previously; we'll have them when you need them, part number 7601(call). If you are running a flat tappet or a solid roller cam with more than 0.600" lift we suggest a stud girdle P/N JPP 1194. We don't think the practice of installing 7/16" studs is a safe modification. Look at the boss for the exhaust studs, even the reinforced ones on the R/T heads. We are not comfortable with putting a stud that size in a boss that small. It won't strip out; it may just break off causing you to have to start over with a new head. The stud girdle can be used with the 5/16" bottom stud set-up too because it is 3/8" on top. The stud girdle will allow will you to run any spring pressure you want.

|

A thin hex stud with a 10mm bottom section

|

The rather weak appearing R/T exhaust stud boss

The rather weak appearing R/T exhaust stud boss

on the right, shown with the original 5/16" hole. There

won't be much support left when it is drilled out to 7/16"

|

Now, to those of you planning on using a flat tappet cam, either hydraulic or solid and stock or roller rockers, there will be an interference problem between the push rod and tunnel or opening in the head for the pushrod. This is due to the fact that the Magnum heads.

Were originally designed for a tall hydraulic lifter. When you use a shorter flat tappet lifter the angle at which the pushrod goes thru the head changes. We mill this area out on a vertical mill. We are working on a drill fixture so you can again do it at home with a drill.

|

This is where the pushrod hits the heads when using flat tappet cams

|

|

LA heads: Finding good candidates for porting is getting very difficult, most of them are cracked or rusted so bad that they are not reliable when ported. We will only offer 2 ported version from now on. Our regular Stage I, and our new modified Stage II+ that has a 2.05" intake and a 1.625" exhaust valve, both with 11/32" stems. The porting flow numbers and curve will be a result of developments by us and many other cylinder head specialists, and are different than we have seen in the past. This head will flow more air in the lower and mid-lift range than it does at the very top of the flow curve. The maximum flow will be the same as before or better but we have achieved it earlier in the curve. We like to see the maximum flow on this head at 0.500"/ 0.550" lift instead of at 0.650". The result is more area under the curve hence, more total flow with a smaller port volume regardless of the cam being used. All with the bottom line being a fatter power curve! As time permits we will bring these changes to the Big Block iron heads, as well.

|

|

|

|

|